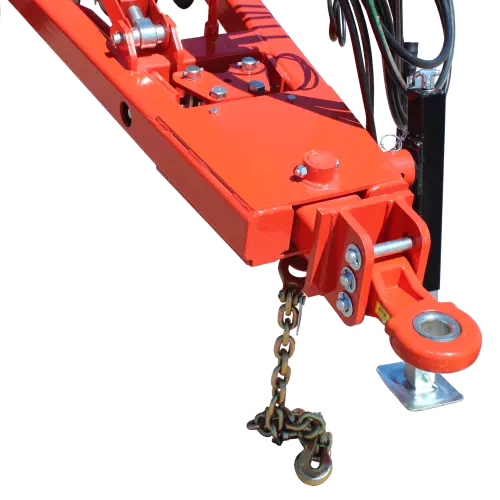

| CAT IV Articulating Ball Hitch for 2" Pin | CAT IV Articulating Ball Hitch for 2" Pin | CAT IV Articulating Ball Hitch for 2" Pin | CAT IV Articulating Ball Hitch for 2" Pin | CAT IV Articulating Ball Hitch for 2" Pin |

| Rigid, Mechanical Adjustable, Self-Leveling Tongue | Rigid, Mechanical Adjustable, Self-Leveling Tongue | Rigid, Mechanical Adjustable, Self-Leveling Tongue | Guardian Hitch™ (Cushion Tongue) | Guardian Hitch™ (Cushion Tongue) |

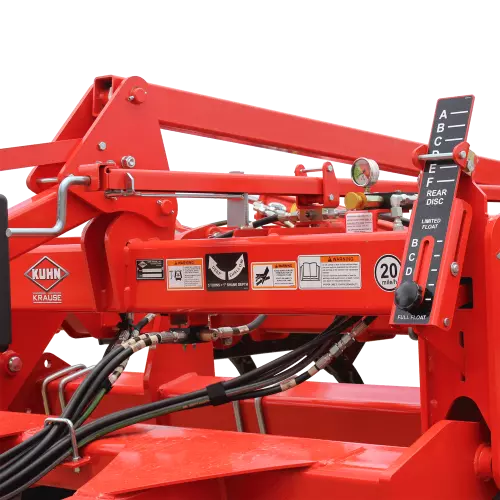

| Single Point Hydraulic Depth Control | Single Point Hydraulic Depth Control | Single Point Hydraulic Depth Control | Single Point Hydraulic Depth Control | Single Point Hydraulic Depth Control |

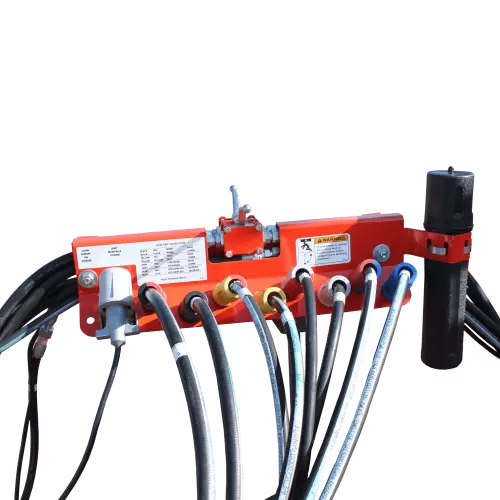

| Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses | Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses | Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses | Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses | Color-Coded Hydraulic Hose Grips, All Hydraulic Hoses |

| 25" x ¼" Smooth | 25" x ¼" Smooth | 25" x ¼" Smooth | 25" x ¼" Smooth | 25" x ¼" Smooth |

| 8" Spacing, Adjustable Constant Pressure Hydraulic, Heavy-Duty 6" Bell Diameter Ductile Iron Spools, 1-¾" Diameter Round Alloy Tie Rod with Maintenance-Free PEER® TILLXTREME™ Bearings, C-Type Rock-Flex™ Bearing Arms 1-¼" x 2-½" | 8" Spacing, Adjustable Constant Pressure Hydraulic, Heavy-Duty 6" Bell Diameter Ductile Iron Spools, 1-¾" Diameter Round Alloy Tie Rod with Maintenance-Free PEER® TILLXTREME™ Bearings, C-Type Rock-Flex™ Bearing Arms 1-¼" x 2-½" | 8" Spacing, Adjustable Constant Pressure Hydraulic, Heavy-Duty 6" Bell Diameter Ductile Iron Spools, 1-¾" Diameter Round Alloy Tie Rod with Maintenance-Free PEER® TILLXTREME™ Bearings, C-Type Rock-Flex™ Bearing Arms 1-¼" x 2-½" | 8" Spacing, Adjustable Constant Pressure Hydraulic, Heavy-Duty 6" Bell Diameter Ductile Iron Spools, 1-¾" Diameter Round Alloy Tie Rod with Maintenance-Free PEER® TILLXTREME™ Bearings, C-Type Rock-Flex™ Bearing Arms 1-¼" x 2-½" | 8" Spacing, Adjustable Constant Pressure Hydraulic, Heavy-Duty 6" Bell Diameter Ductile Iron Spools, 1-¾" Diameter Round Alloy Tie Rod with Maintenance-Free PEER® TILLXTREME™ Bearings, C-Type Rock-Flex™ Bearing Arms 1-¼" x 2-½" |

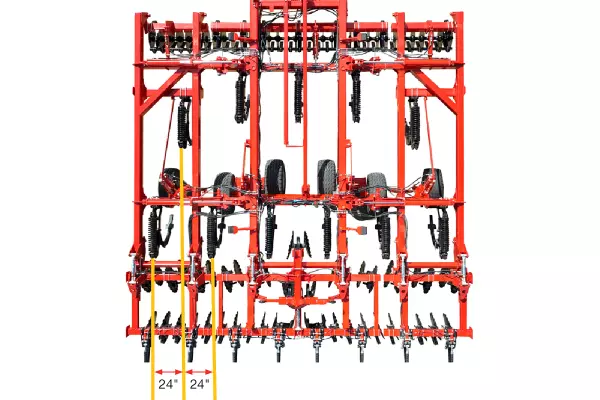

| 3,000 lb Point Load Spring Reset Parabolic Sub-Soil Shank, 1-¼ x 4" Shank Size with Wear Bar, 21" Trip Height, 39" Underframe Clearance, 16" Working Depth | 3,000 lb Point Load Spring Reset Parabolic Sub-Soil Shank, 1-¼ x 4" Shank Size with Wear Bar, 21" Trip Height, 39" Underframe Clearance, 16" Working Depth | 3,000 lb Point Load Spring Reset Parabolic Sub-Soil Shank, 1-¼ x 4" Shank Size with Wear Bar, 21" Trip Height, 39" Underframe Clearance, 16" Working Depth | 3,000 lb Point Load Spring Reset Parabolic Sub-Soil Shank, 1-¼ x 4" Shank Size with Wear Bar, 21" Trip Height, 39" Underframe Clearance, 16" Working Depth | 3,000 lb Point Load Spring Reset Parabolic Sub-Soil Shank, 1-¼ x 4" Shank Size with Wear Bar, 21" Trip Height, 39" Underframe Clearance, 16" Working Depth |

| Double K® Chromium Carbide, 7" Winged Ripper Points | Double K® Chromium Carbide, 7" Winged Ripper Points | Double K® Chromium Carbide, 7" Winged Ripper Points | Double K® Chromium Carbide, 7" Winged Ripper Points | Double K® Chromium Carbide, 7" Winged Ripper Points |

| (4) 360/65R17.5 Metric Tires, Walking Beams, Slip-In Spindles, Maintenance-Free Spherical Bearings, 8-Bolt Heavy-Duty Hubs | (4) 360/65R17.5 Metric Tires, Walking Beams, Slip-In Spindles, Maintenance-Free Spherical Bearings, 8-Bolt Heavy-Duty Hubs | (4) 360/65R17.5 Metric Tires, Walking Beams, Slip-In Spindles, Maintenance-Free Spherical Bearings, 8-Bolt Heavy-Duty Hubs | (4) 440/55R18 Metric Tires, Walking Beams, Slip-In Spindles, Maintenance-Free Spherical Bearings, 8-Bolt Heavy-Duty Hubs | (4) 440/55R18 Metric Tires, Walking Beams, Slip-In Spindles, Maintenance-Free Spherical Bearings, 8-Bolt Heavy-Duty Hubs |

| Not Applicable | Not Applicable | Not Applicable | (1) 360/65R17.5 per Wing 8-Bolt Hub | (1) 360/65R17.5 per Wing 8-Bolt Hub |

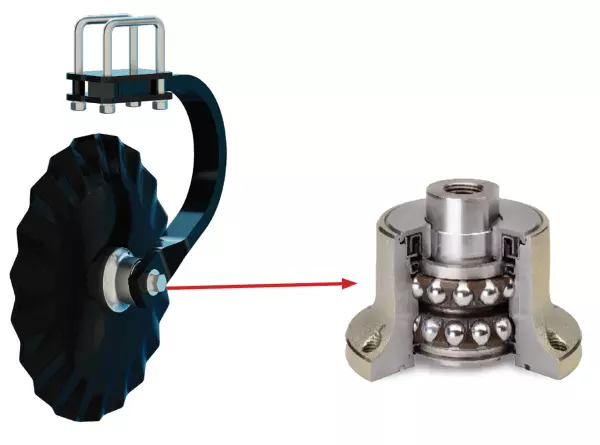

| Maintenance-Free, Double Angular Contact Bearing, 6-Bolt Hub for Blades 24" x 6 Gauge, Fluted Shallow Concavity Disc Blades, 12" Blade Spacing, Remote Single-Point Hydraulic Lower Limit Stop, Reversed Tandem Design | Maintenance-Free, Double Angular Contact Bearing, 6-Bolt Hub for Blades 24" x 6 Gauge, Fluted Shallow Concavity Disc Blades, 12" Blade Spacing, Remote Single-Point Hydraulic Lower Limit Stop, Reversed Tandem Design | Maintenance-Free, Double Angular Contact Bearing, 6-Bolt Hub for Blades 24" x 6 Gauge, Fluted Shallow Concavity Disc Blades, 12" Blade Spacing, Remote Single-Point Hydraulic Lower Limit Stop, Reversed Tandem Design | Maintenance-Free, Double Angular Contact Bearing, 6-Bolt Hub for Blades 24" x 6 Gauge, Fluted Shallow Concavity Disc Blades, 12" Blade Spacing, Remote Single-Point Hydraulic Lower Limit Stop, Reversed Tandem Design | Maintenance-Free, Double Angular Contact Bearing, 6-Bolt Hub for Blades 24" x 6 Gauge, Fluted Shallow Concavity Disc Blades, 12" Blade Spacing, Remote Single-Point Hydraulic Lower Limit Stop, Reversed Tandem Design |

| 24/7® Soil Conditioning Reel, Heavy-Duty Solid Round Bar Spiral Reels, PEER® TILLXTREME™ Maintenance-Free Bearings | 24/7® Soil Conditioning Reel, Heavy-Duty Solid Round Bar Spiral Reels, PEER® TILLXTREME™ Maintenance-Free Bearings | 24/7® Soil Conditioning Reel, Heavy-Duty Solid Round Bar Spiral Reels, PEER® TILLXTREME™ Maintenance-Free Bearings | 24/7® Soil Conditioning Reel, Heavy-Duty Solid Round Bar Spiral Reels, PEER® TILLXTREME™ Maintenance-Free Bearings | 24/7® Soil Conditioning Reel, Heavy-Duty Solid Round Bar Spiral Reels, PEER® TILLXTREME™ Maintenance-Free Bearings |

| (1) 2" x 3.25" Cylinder and Hoses per Carrier Arm | (1) 2" x 3.25" Cylinder and Hoses per Carrier Arm | (1) 2" x 3.25" Cylinder and Hoses per Carrier Arm | (1) 2" x 3.25" Cylinder and Hoses per Carrier Arm | (1) 2" x 3.25" Cylinder and Hoses per Carrier Arm |

| Hydraulic Valves, Transport and Wing Fold, Slow Moving Vehicle Sign, High-Visibility LED Lighting | Hydraulic Valves, Transport and Wing Fold, Slow Moving Vehicle Sign, High-Visibility LED Lighting | Hydraulic Valves, Transport and Wing Fold, Slow Moving Vehicle Sign, High-Visibility LED Lighting | Hydraulic Valves, Transport and Wing Fold, Slow Moving Vehicle Sign, High-Visibility LED Lighting | Hydraulic Valves, Transport and Wing Fold, Slow Moving Vehicle Sign, High-Visibility LED Lighting |